A Feature Article by the Mining Technology Division

Ensuring the stability of open pit walls is a critical concern in surface mining operations. It is paramount for safeguarding human lives and equipment, maintaining operational continuity, protecting the environment, and sustaining the economic viability of a mining project.

Recent advancements in drone technology offer promising solutions to overcome challenges in slope stability analyses. The key advantage of drones in surveying and mapping is the capability to execute autonomous low-altitude flights, allowing for the collection of close-range, high-resolution images at a minimal cost. By using photogrammetric techniques and dedicated geographic information and modeling software, specialized outputs such as orthomosaics, digital elevation models, and 3D point clouds and meshes with survey-grade accuracy can be produced within hours to a few days of post-processing.

The landslide at the Carmen Pit of Carmen Copper Corporation in December 2020 underscores the need for advanced geotechnical analyses and monitoring systems in mining operations. Such incidents not only result in the loss of lives and equipment but also disrupt operations, leading to significant financial losses, and worse, environmental catastrophes. Traditional methods of slope stability analysis face limitations such as inaccessibility, technical expertise requirements, and time-consuming data collection processes. In response, the Mining Technology Division embarked on a Research and Development Project titled "Workflow Development for Rapid Rock Slope Stability Analysis: 3D Modelling of Open Pit Walls using Drone Photogrammetry" from 2023 to 2024. The project seeks to leverage drone technology to streamline data collection, improve accuracy, and enhance the efficiency of slope stability analysis.

Progress Report

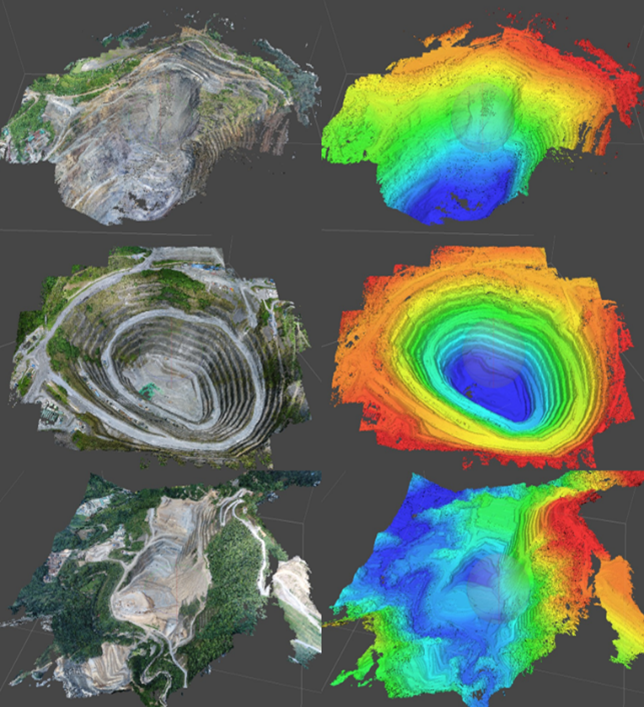

In 2023, fieldworks were conducted at three open pit mining sites—Carmen Copper Corporation, OceanaGold Philippines, Inc., and FCF Minerals Corporation. The study involved using drones equipped with high-resolution cameras to capture detailed aerial images. The researchers experimented with drone flight parameters to optimize 3D modeling of pit walls. Despite challenges such as large data size and geospatial inaccuracies, significant progress was made in refining flight parameters and enhancing model accuracy.

Initially, the study revealed insights into the effectiveness of different flight parameters in capturing detailed pit wall structures. In one of the mine sites visited, a ground sampling distance (GSD) of approximately 1 cm/pix was found ideal for maximizing model resolution. However, challenges such as geospatial inaccuracies due to the limited number of ground control points (GCPs) were observed. In contrast, succeeding fieldworks demonstrated improved model accuracy through the implementation of increased number of GCPs and optimized flight sections.

Left: Pit models constructed from drone captured images;

Right: Digital Elevation Models derived from the pit models.

Way Forward

Moving forward, the research will focus on reviewing algorithms to extract discontinuity planes and integrating 3D models with geographic information systems (GIS) for automated calculations and classifications, and ultimately, towards the formulation of slope stability criteria. Additionally, efforts will be made to address challenges encountered during image processing in 2023.

The ongoing research project highlights the transformative potential of drone technology in advancing rock slope stability analysis in surface mining operations. By harnessing the capabilities of drones for rapid data collection and analysis, mining companies can mitigate risks, improve safety, and optimize operational performance. As the project progresses, its findings are expected to contribute significantly to the body of knowledge in geotechnical engineering and shape best practices in the mining industry.