The Metallurgical Technology Division (MeTD) of the Mines and Geosciences Bureau (MGB) had successfully completed the conduct of its collaborative project with the Department of Science and Technology – Philippine Council for Industry, Energy and Emerging Technology Research and Development (DOST-PCIEERD) entitled “Pilot Scale Production of Nickel Pig Iron Using Low Grade Laterite Ores”.

The two (2)-year project which commenced in July 2018 had been concluded last December 2020, despite the adversities caused by the global pandemic. Led by MeTD Senior Metallurgist, Engr. Bernardo V. Bitanga, the said project generally aimed to investigate the technical feasibility of using low grade laterite ores for shaft furnace ironmaking technology. It gears towards sustainable mineral processing in adherence to the provision of Section 8 of Executive Order No. 79 s. 2012 on Value-Adding Activities and Development of Downstream Industries for the Mineral Sector.

Low grade laterites from six (6) Philippine provinces – Zambales, Isabela, Palawan, Dinagat Islands, Surigao del Norte, and Surigao del Sur were utilized throughout the project duration to produce nickel pig iron or pig iron, an intermediate product of ironmaking for stainless-steel production. Such was made possible thru the assistance of the following nickel mining companies in the aforementioned provinces: LNL Archipelago Minerals, Inc., Dinapigue Mining Corporation, Berong Nickel Corporation, Century Peak Corporation, Platinum Group Metals Corporation, and CTP Construction and Mining Corporation.

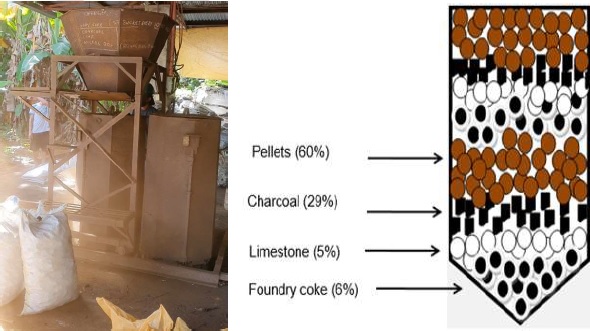

The project team acquired the services of Ferromet Resources Inc., for the use of their shaft furnace facility in San Ildefonso, Bulacan, to simulate the blast furnace process. The resulting grades of the produced crude pig iron were almost comparable to the commercial basic pig iron. Analysis of slag also showed significant Scandium content.

According to Engr. Bitanga “Converting low grade laterite ores into pig iron via the blast/shaft furnace technology is feasible. However, the composition of the ore plays a critical role in its reducibility and therefore, will dictate its suitability for the process”. He also emphasized the Project Team’s gratitude to all who supported this pursuit, especially to DOST-PCIEERD.

The technical results gathered from the concluded project instigated MeTD and DOST – Metals Industry Research and Development Center to propose a Research Program to DOST. The Program is composed of three (3) projects, two (2) of which namely, “Technical Study on the Use of Blended Laterite-Iron Sand as Feed Materials for Shaft Furnace Ironmaking Technology” and “Recovery of Scandium from Laterite Based Pig Iron Slag by Dry Digestion and Precipitation” will be headed by MeTD. The Program was already approved by the DOST Executive Committee last July 22, 2020 and is deemed to commence immediately upon but not later than (2) months after the release of funds early this 2021.

By: Metallurgical Technology Division

Shaft Furnace Facility of Ferromet Resources, Inc. Drying of Laterite Samples for Moisture Removal

Pulverizing of Laterite Samples Using Hammer Mill Pelletizing of Laterite Sample with Fluxes

Preparation of Furnace Charge Material/Burden

Hoisting of Sample Bucket into the Furnace Opening Tapping and Molding of Molten Products

Pig Iron Product